The challenge of fabricating nanowires directly on silicon substrates for the creation of the next generation of electronics has finally been solved by researchers from Tokyo Tech. Next-generation spintronics will lead to better memory storage mechanisms in computers, making them faster and more efficient.

As our world modernizes faster than ever before, there is an ever-growing need for better and faster electronics and computers. Spintronics is a new system which uses the spin of an electron, in addition to the charge state, to encode data, making the entire system faster and more efficient. Ferromagnetic nanowires with high coercivity (resistance to changes in magnetization) are required to realize the potential of spintronics. Especially L10-ordered (a type of crystal structure) cobalt–platinum (CoPt) nanowires.

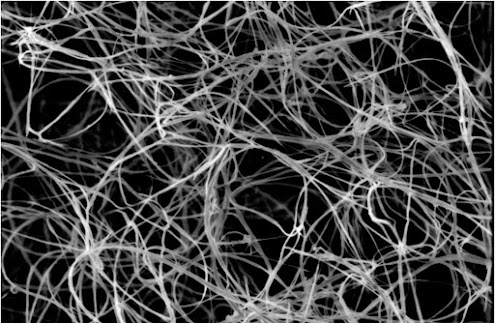

Conventional fabrication processes for L10-ordered nanowires involve heat treatment to improve the physical and chemical properties of the material, a process called annealing on the crystal substrate; the transfer of a pattern onto the substrate through lithography; and finally, the chemical removal of layers through a process called etching. Eliminating the etching process by directly fabricating nanowires onto the silicon substrate would lead to a marked improvement in the fabrication of spintronic devices. However, when directly fabricated nanowires are subjected to annealing, they tend to transform into droplets as a result of the internal stresses in the wire.

.jpg)

.jpg)