|

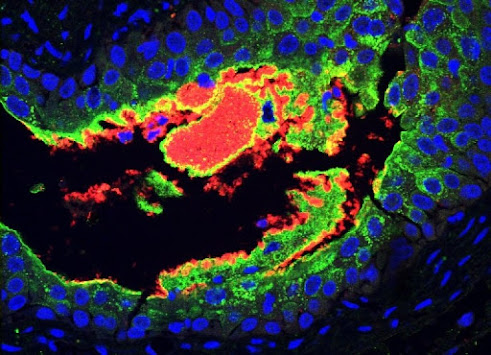

| A photo of the 3D color printed McLaren 17D Formula One front wing endplate. The colors visualize the complex flow a fraction of a millimeter away from the wing's surface. Photo credit: KAUST |

In Formula One race car design, the manipulation of airflow around the car is the most important factor in performance. A 1% gain in aerodynamics performance can mean the difference between first place and a forgotten finish, which is why teams employ hundreds of people and spend millions of dollars perfecting this manipulation.

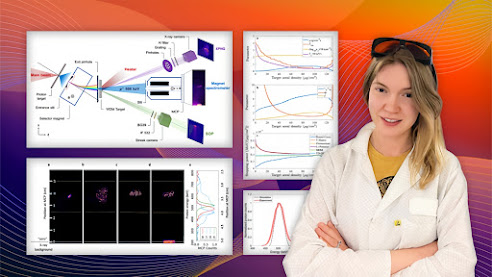

Of special interest is the design of the front wing endplate, which is critical for the drag and lift of the car. Dr. Matteo Parsani, associate professor of applied mathematics and computational science at King Abdullah University of Science and Technology (KAUST), has led a multidisciplinary team of scientists and engineers to simulate and 3D color print the solution of the McLaren 17D Formula One front wing endplate. The work is the result of a massively high-performance computing simulation, with contributing expertise by research scientist Dr. Lisandro Dalcin of the KAUST Extreme Computing Research Center (ECRC), directed by Dr. David Keyes, and also the Advanced Algorithm and Numerical Simulations Lab (AANSLab), and Prototyping and Product Development Core Lab (PCL).

.jpg)